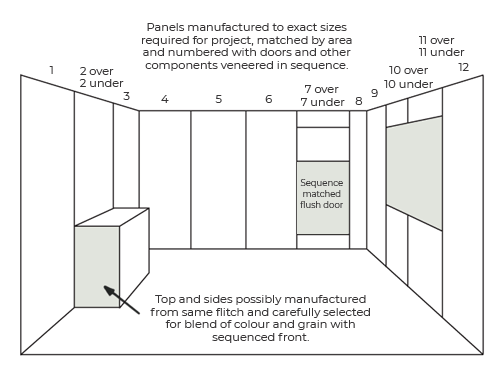

This method of panel matching achieves maximum grain continuity since all panels, doors, and other veneered components are made to the exact sizes required and in exact veneer sequence. If possible, flitches should be selected that will yield sufficient veneer to complete a prescribed area or room. If more than one flitch is needed, flitch transition should be accomplished at the least noticeable, predetermined location.

This method requires careful site coordination and relatively long lead times.

Panels cannot be manufactured until site conditions can be accurately measured and detailed. This panel matching method is more expensive and expresses veneering in its most impressive manner.

Note: Unless otherwise specified the grain direction is along the length (or height) of a panel, called long band.