Veneer is produced as a thin layer of timber that is uniform in thickness. The veneer is normally between 0.5 and 0.85mm thick in Australia and New Zealand.

Timber veneer is from a natural and renewable resource competing with non-renewable commodities like steel, aluminium and plastics.

The surface coverage of veneer is approximately forty times more than 25mm timber, which makes it the most economical way of utilising precious wood. One cubic metre of log produces around 1,000 square metres of real timber in veneer form. No other form of woodworking material results in such an efficient use with minimal wastage.

Some of the benefits of using real timber in veneer form include:

A design collaboration with nature

The natural variation of timber means every log, and therefore every project, is individual. No two veneers are exactly alike. The ‘fingerprints’ of nature lift your designs above what is achievable with man-made alternatives. You can choose from a vast array of timber species, colours, and grains. The final veneer finish is virtually identical to solid timber.

The warmth and depth of timber

Timber veneers add natural warmth and ambience to projects and is gentle to the touch.

Prestige and versatility

Timber veneer is a sought-after, premium decorative finish that adds prestige and style to furniture and joinery. Timber veneers can be moulded to fit many shapes, and when adhered to a stable commodity substrate, provided the versatility of solid timber, our oldest, yet most modern material

Maximises nature’s resources

Each metre of timber typically provides around 1,000 slices of timber veneer, making it a highly efficient and sustainable use of wood

Ecologically sensible solution

Timber veneer is a 100% natural product and not made from petro-chemicals. The industry is committed to sustainable forest resources.

One cubic metre of log produces around 1,000 square metres of real timber in veneer form

Veneer is produced by slicing or peeling logs. It is sliced at approximately 0.6mm (this is normal thickness for the Australian market) or can be peeled at various thicknesses.

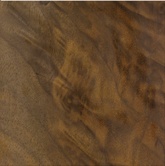

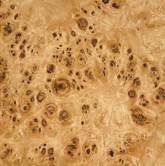

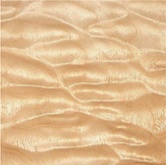

Several cut methods are used to create various wood grain patterns. The most commonly produced grains are: Crown, Quarter, and Rotary. However, other cuts exist and highlight specific features such as Birdseye, Quiltes, Pommele or Burl/Burr.

The pattern seen on the surface of a veneer is known as the ‘figure’. It is determined by a log’s natural features or the way the flitch (piece of log) is cut.

Natural features

The frequency of growth rings, the colour tone variations between earlywood and latewood, deviations from natural grain (wavy, curly or interlocked grain), medullary rays, markings and pigments in the wood structure, and burls or curls.